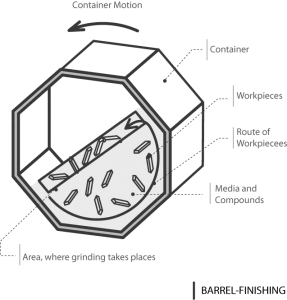

Mass finishing in barrels

You can have your metal or plastic parts deburred, rounded and polished with barrel finishing / tumble finishing. By a slow rotation of the barrel, the components are processed particularly gently.

In barrel finishing, the workpieces to be machined are placed together with plastic or ceramic media in a round container (the container is called a barrel). A slow rotational movement of the barrel creates a relative movement between the workpieces and the grinding wheel and abrasion occurs on the workpieces. Depending on the objective, different media is used (plastic or ceramic, originally sand and stones). This allows workpieces to be deburred, rounded or polished.

Barrel finishing is the original type of mass finishing. It is also referred to as barrelling, tumble finishing, tumbling, rumbling or “trowalizing” – after the company Walther Trowal. Walther Trowal was one of the first companies in Germany to make industrial use of barrel finishing.