Deburring, rounding and polishing of high-quality workpieces

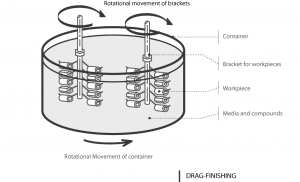

Sensitive workpieces can be efficiently deburred, rounded and polished using the drag finishing / drag grinding process. In the drag finishing process (or similar stream finishing or pulse finishing for Otec systems and Surf finishing for Rösler systems), each workpiece is individually clamped into the machine and subsequently dragged through grinding or polishing media. Depending on the desired processing result (from deburring to rounding to high gloss polishing in hand polishing quality) different grinding and polishing media can be used.