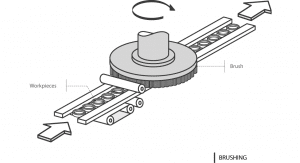

The brushing process gives a special grinding pattern to the surface of your workpieces. In addition, your components will be deburred (brush deburring), rounded or polished. Your workpieces will be precisely and partially machined. This gives your workpieces precisely defined radii and contours at the edges.

We use different brushes and pastes for achieving different process results. Depending on your requirements the following results can be achieved:

Deburring / edge rounding: The most common application is probably brush deburring. Here, burrs are efficiently removed during the process. This also improves the quality of the edges. In particular, tools such as indexable inserts can obtain precisely defined radii (edge rounding).

Polishing / Smoothing: Special brushes and polishing pastes can be used to reduce roughness on workpiece surfaces and to polish up your workpieces.

Matting / Structuring: By using certain brushes, the surface structure can be changed. The roughness can be reduced and the typical brushed appearance can be achieved.