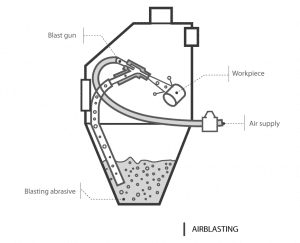

Blasting with glass beads, sand (standing blasting), corundum, stainless steel or natural materials (such as walnut shell granulate) gives your workpieces structured and satin-finished surfaces. This allows you to meet both optical and functional requirements. We blast in blasting cabins with compressed air (injector blasting or air blasting).

Blasting for optical applications: You receive silk-matt, satin-finished surfaces in various degrees of gloss. Due to the different size of the granulate used (grain size or grain size) as well as the different pressure, different surface optics can be produced during blasting.

Blasting for technical applications: A certain surface roughness or contact ratio is achieved. This serves to improve tribological properties (e.g. in rolling bearings). In addition, the service life of moulds and tools can be increased (shot peening).