Centrifugal disc finishing can help you to deburr, round and polish your workpieces. It is particularly suitable for the machining of filigree and difficult components. The costs for machining are comparatively low due to the short machining times.

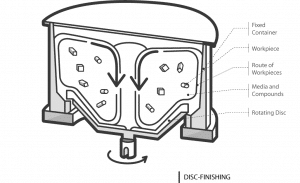

In centrifugal grinding (also centrifugal vibratory grinding), workpieces, grinding wheels and compounds are fed into a machine with a rotating plate. The rotating disc sets the mass in a rotary motion and a relative movement between workpieces and grinding wheels is created. This results in a material removal on the workpiece surfaces.

For each workpiece, individually suitable grinding media and compounds must be selected. The choice depends on factors such as workpiece geometry, material and objective. Optimum results can only be achieved through precise coordination.